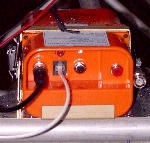

Ignition Switch:

The ignition switch starts your engine "IF" you installed the GPL Starter on the engine. Otherwise, you need to turn the key to "Both" and pull start your engine.The connections on the back are numbered on the fact sheet to the right and wires as follows. Use an 8 wire/18 AWG, shielded cable to run from the instrument panel to the engine firewall.

1. To the right mag., wired to Black/Yellow wire #1 from the engine. NOTE: The jumper "IS NOT" used.

2. To the left mag., wired to Black/Yellow wire #2 from the engine.

3. Power, wired to the +12v Power Bus under instrument panel.

4. Start, wired directly to the small pole on the left side of the starter solenoid, same as the Master Power Switch.

5. Ground, run a "green" wire to the "brown" engine block wire.

As the "BO" terminal is not used and was touching the lower gauge, it was removed from the switch.

The second ignition switch is for a pull start engine, no GPL starter.